Virtual Factory Tour

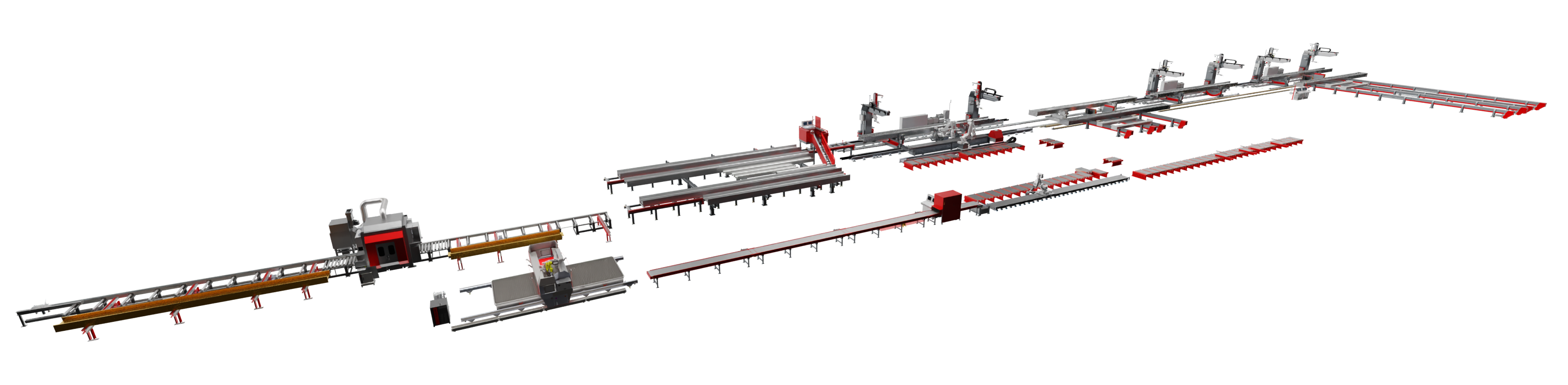

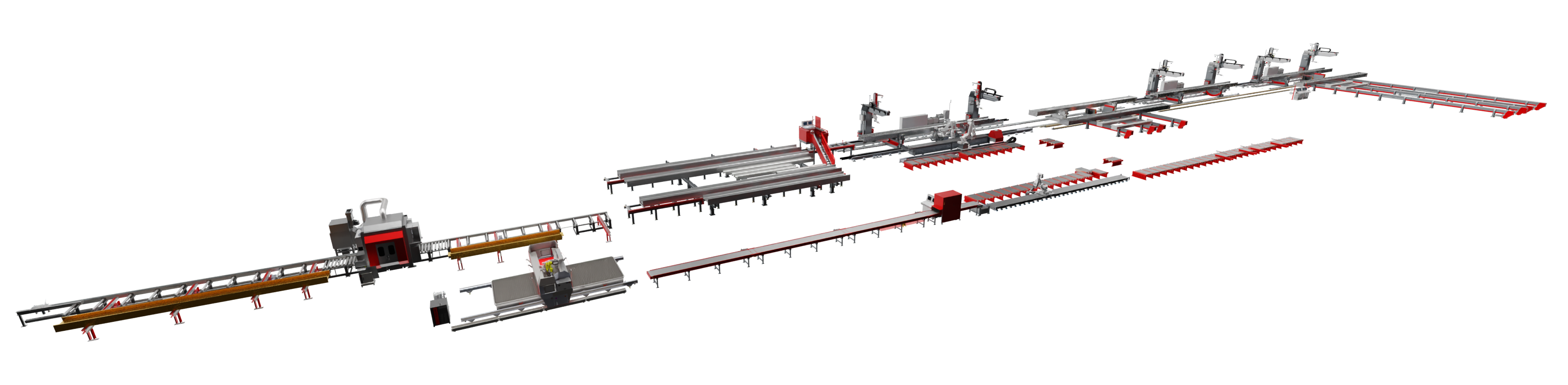

PythonX STRUCTURAL is the leading all-in-one robotic plasma system in the world trusted by more end-users with over 800+ systems installed worldwide. The system takes in your drawing files and automatically processes beams, channels, angles, square and rectangular tubes, as well as plate, all on one machine. In addition, the machine produces bolt holes that are AISC and EN1090 compliant. Additional cutting capabilities include copes, slots, cutouts, cut to length, miter cuts, weld preps, and scribe part/layout marks, all done in one place, eliminating countless hours of material handling in between operations. Because everything is done on one machine, saving you valuable shop space, you'll be able to streamline your operations. PythonX STRUCTURAL allows you to automate structural steel fabrication operations in your plant, saving you time and money.

The Zeman Steel Beam Welder (SBW) is a robotic welding cell that can either weld out manually assembled beams or beams from an SBA, pre-assembled, and partially welded using the same work file generated for the SBA. A robust and reliable design, running on high-precision tracks designed for the steel industry and its environment, paired with a leading industrial robot equipped with a laser vision system to ensure the best accuracy and quality welds within the structural steel industry. A heavy-duty design with a fully automated rotation process allows 360° processing of the beams. There are different models and machine configurations possible (e.g. one or two welding towers, automated material handling with the Side Discharger, etc.) to meet the needs of the individual fabricator.

The ENSPECTORTM was developed to facilitate the plate management of steel fabricators and automate their structural steel beam factory. This intelligent scanning system inspects and identifies each part, assigns them to the given project, and runs a quality check if the scanned part fulfills your requirements, an essential step to ensure high standards and perfect results. After evaluating the characteristics of a piece, a rapidly moving robot marks and assigns the part to the designated box, which is equipped with an RFID chip to maintain visibility throughout the production process. In addition to this system, Zeman also offers an Autonomous Guided Vehicle (AGV) to connect your scanning system directly to the Zeman SBA to automate your factory further.

The Zeman Steel Beam Assembler (SBA) represents the flagship of Lincoln Electric’s fully automated structural steel beam assembly and welding production line. The machine can fit and weld large amounts of steel accurately and efficiently. Different models and various machine configurations are available to meet the needs of the individual fabricator. It only takes a few minutes to auto-generate the workflow without programming or teaching the robots, and it doesn’t stop there. The big time and cost savings are in the assembly process, where we can achieve an efficiency increase of over 90% vs. manual fitting with only one operator.